APG-HFHM

Base product: SURGE-ARRESTORS

Arrestor Plus® Quarterwave Surge Arrestor 806-2170MHz, with interface types 4.3-10 Female and 4.3-10 Male

Specifications

Product classification

| Product Type | Quarter wave shorting stub |

| Product Brand | Arrestor Plus® |

| Ordering Note | ANDREW® non-standard product |

General specifications

| Device Type | dc Pass |

| Inner Contact Plating | Silver |

| Interface | 4.3-10 Female |

| Interface 2 | 4.3-10 Male |

| Outer Contact Plating | Trimetal |

Dimensions

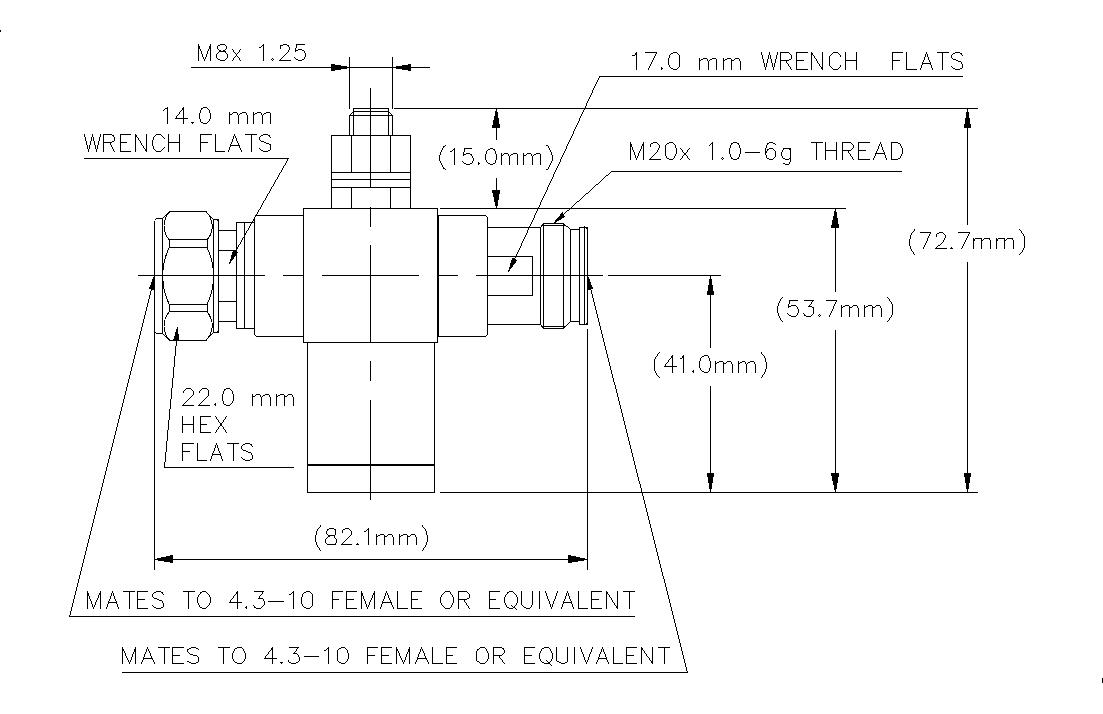

| Height | 72.7 mm | 2.862 in |

| Width | 25 mm | 0.984 in |

| Length | 82.1 mm | 3.232 in |

Outline drawing

| Click on image to enlarge. |

Electrical specifications

| 3rd Order IMD Gain | -115 dB |

| 3rd Order IMD Test Method | Two +43 dBm carriers |

| Insertion Loss, typical | 0.07 dB |

| Connector Impedance | 50 ohm |

| Lightning Surge Current | 10 kA |

| Lightning Surge Current Waveform | 8/20 waveform |

| Operating Frequency Band | 806 – 2170 MHz |

| Peak Instantaneous Power (PIP) | 150 kW RF |

Return loss/vswr

| Frequency band | Vswr | Return loss (db) |

| 806–960 MHz | 1.101 | 26.36 |

| 960–1710 MHz | 1.210 | 20.50 |

| 1710–2000 MHz | 1.101 | 26.36 |

| 2000–2170 MHz | 1.150 | 23.13 |

Mechanical specifications

| Coupling Nut Proof Torque | 10 N-m | 88.507 in lb |

| Coupling Nut Retention Force | 449.27 N | 101 lbf |

| Coupling Nut Retention Force Method | MIL-C-39012C-3.25, 4.6.22 |

| Interface Durability | 100 cycles |

| Interface Durability Method | IEC 61169-16:9.5 |

| Mechanical Shock Test Method | MIL-STD-202F, Method 213B, Test Condition C |

Environmental specifications

| Operating Temperature | -45 °C to +85 °C (-49 °F to +185 °F) |

| Storage Temperature | -70 °C to +150 °C (-94 °F to +302 °F) |

| Attenuation, Ambient Temperature | 20 °C | 68 °F |

| Average Power, Ambient Temperature | 40 °C | 104 °F |

| Corrosion Test Method | MIL-STD-202, Method 101, Test Condition B |

| Immersion Depth | 1 m |

| Immersion Test Mating | Mated |

| Immersion Test Method | IEC 60529:2001, IP68 |

| Moisture Resistance Test Method | MIL-STD-202, Method 106 |

| Thermal Shock Test Method | MIL-STD-202, Method 107, Test Condition A-1, Low Temperature -55 °C |

| Water Jetting Test Mating | Mated |

Regulatory compliance/certifications

| Agency | Classification |

|

CHINA-ROHS

|

Below maximum concentration value |

| ISO 9001:2015 | Designed, manufactured and/or distributed under this quality management system |

| ROHS | Compliant |

| UK-ROHS | Compliant |

| REACH-SVHC | Compliant as per SVHC revision on www.andrew.com/ProductCompliance |

Product classification

| Product Type | Quarter wave shorting stub |

| Product Brand | Arrestor Plus® |

| Ordering Note | ANDREW® non-standard product |

General specifications

| Device Type | dc Pass |

| Inner Contact Plating | Silver |

| Interface | 4.3-10 Female |

| Interface 2 | 4.3-10 Male |

| Outer Contact Plating | Trimetal |

Dimensions

| Height | 72.7 mm | 2.862 in |

| Width | 25 mm | 0.984 in |

| Length | 82.1 mm | 3.232 in |

Electrical specifications

| 3rd Order IMD Gain | -115 dB |

| 3rd Order IMD Test Method | Two +43 dBm carriers |

| Insertion Loss, typical | 0.07 dB |

| Connector Impedance | 50 ohm |

| Lightning Surge Current | 10 kA |

| Lightning Surge Current Waveform | 8/20 waveform |

| Operating Frequency Band | 806 – 2170 MHz |

| Peak Instantaneous Power (PIP) | 150 kW RF |

Return loss/vswr

| Frequency Band | VSWR | Return Loss (dB) |

| 806–960 MHz | 1.101 | 26.36 |

| 960–1710 MHz | 1.210 | 20.50 |

| 1710–2000 MHz | 1.101 | 26.36 |

| 2000–2170 MHz | 1.150 | 23.13 |

Mechanical specifications

| Coupling Nut Proof Torque | 10 N-m | 88.507 in lb |

| Coupling Nut Retention Force | 449.27 N | 101 lbf |

| Coupling Nut Retention Force Method | MIL-C-39012C-3.25, 4.6.22 |

| Interface Durability | 100 cycles |

| Interface Durability Method | IEC 61169-16:9.5 |

| Mechanical Shock Test Method | MIL-STD-202F, Method 213B, Test Condition C |

Environmental specifications

| Operating Temperature | -45 °C to +85 °C (-49 °F to +185 °F) |

| Storage Temperature | -70 °C to +150 °C (-94 °F to +302 °F) |

| Attenuation, Ambient Temperature | 20 °C | 68 °F |

| Average Power, Ambient Temperature | 40 °C | 104 °F |

| Corrosion Test Method | MIL-STD-202, Method 101, Test Condition B |

| Immersion Depth | 1 m |

| Immersion Test Mating | Mated |

| Immersion Test Method | IEC 60529:2001, IP68 |

| Moisture Resistance Test Method | MIL-STD-202, Method 106 |

| Thermal Shock Test Method | MIL-STD-202, Method 107, Test Condition A-1, Low Temperature -55 °C |

| Water Jetting Test Mating | Mated |

| Click on image to enlarge. |

Regulatory compliance/certifications

| Agency | Classification |

|

CHINA-ROHS

|

Below maximum concentration value |

| ISO 9001:2015 | Designed, manufactured and/or distributed under this quality management system |

| ROHS | Compliant |

| UK-ROHS | Compliant |

| REACH-SVHC | Compliant as per SVHC revision on www.andrew.com/ProductCompliance |

Installation & videos

Installation instruction

Documentation & downloads